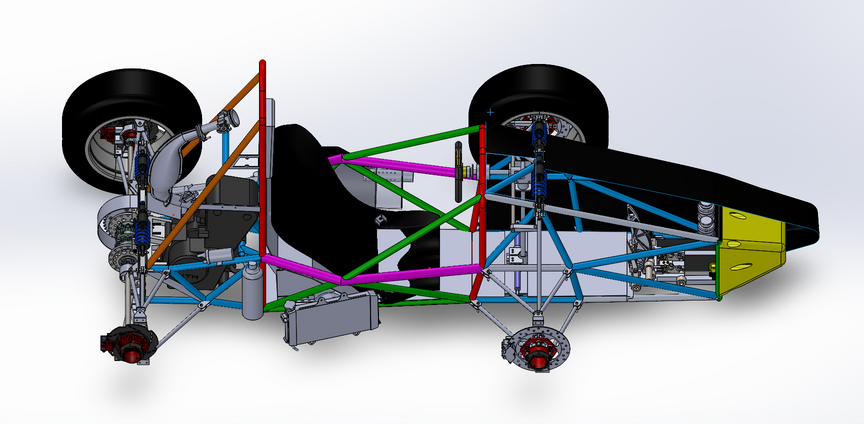

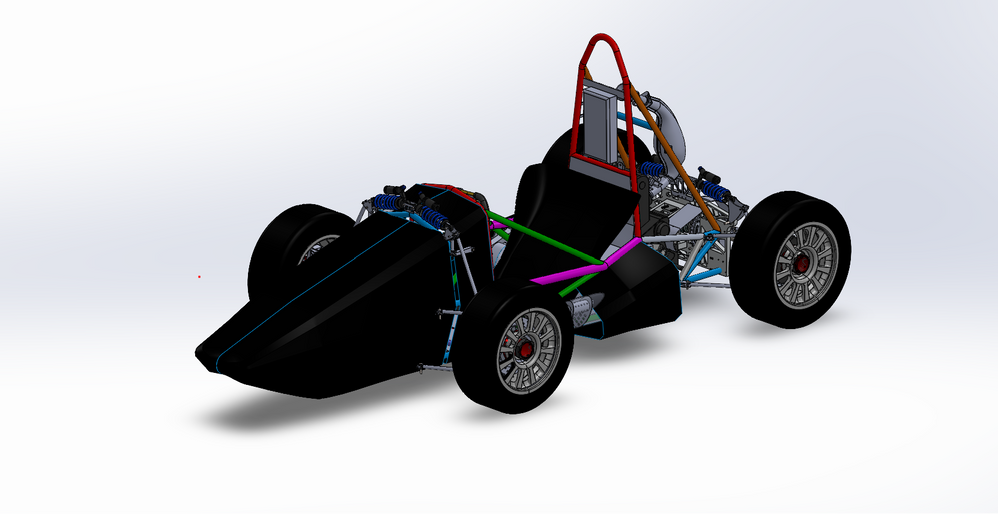

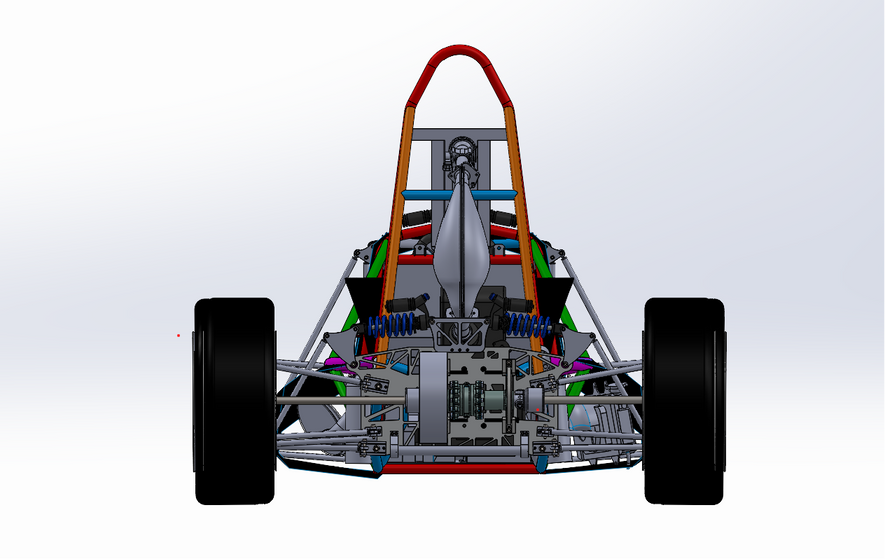

For the main Design competition, I designed various components of car including the drivetrain assembly which increased car’s reliability from last year drastically using jigs to keep the chain in plane.

Earned a commendable 10th rank in a design event held in Formula Bharat

Formula SAE

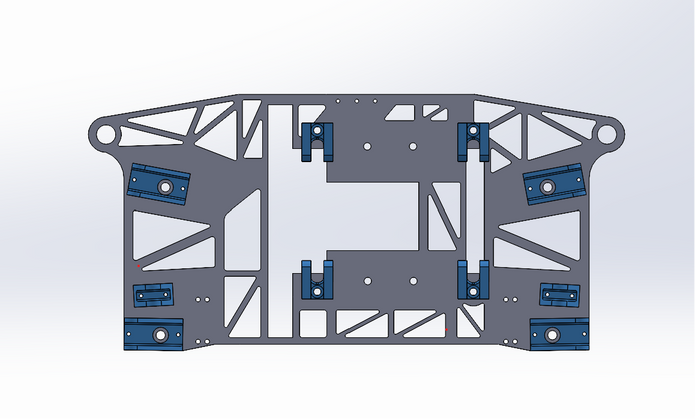

I was the head of the complete FSAE car model for which I used SOLIDWORKS for crafting each component and assembly, crafting 3D-printed mounts for components and actuators.

Spearheaded the Design for Manufacturing (DFM) process for the Drive Train Assembly; designed a weight-reduced sprocket and real bulkhead using FEM, resulting in a 70% reduction, and strategically calculated an optimal drive ratio that vastly improved acceleration performance.

Completed he endurance event and earned a commendable 20th rank in a design event held in Lincoln NE

Contributed to manufacturing the chassis and vehicle integration.

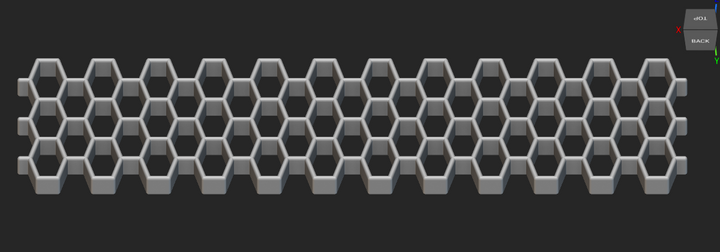

Implemented targeted modifications to the lattice structure based on printer specifications, resulting in a 50% decrease in failure prints and a 15% improvement in overall printing speed.

Printed a 3D lattice structure to form architectural material with lattice and concrete.

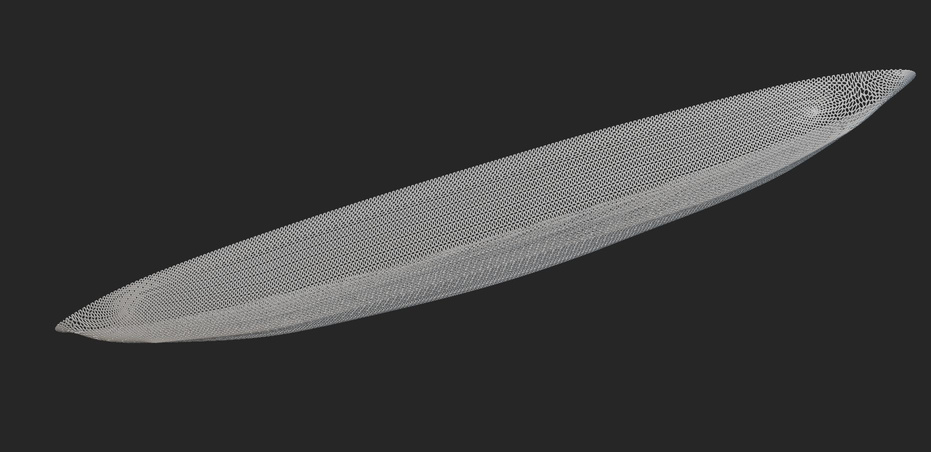

Concrete Canoe

This is a project where I used 3D printed lattice to reinforce concrete and mold it into a canoe which was then set to participate in ASCE competition. This project innovates on using complex 3D lattice structures which also act as a mold for concrete hence reducing fabrication time of canoe.

Enhanced lattice topology through the implementation of diverse nTopology optimization, selecting 'Hexagonal Honeycomb,’ resulting in an impressive 10% augmentation in strength over the previous year and an impressive 30% reduction in overall weight.

Tested different lattices on Universal Tensile Testing Machine until failure and accordingly one was selected and the canoe was modeled in nTopology.

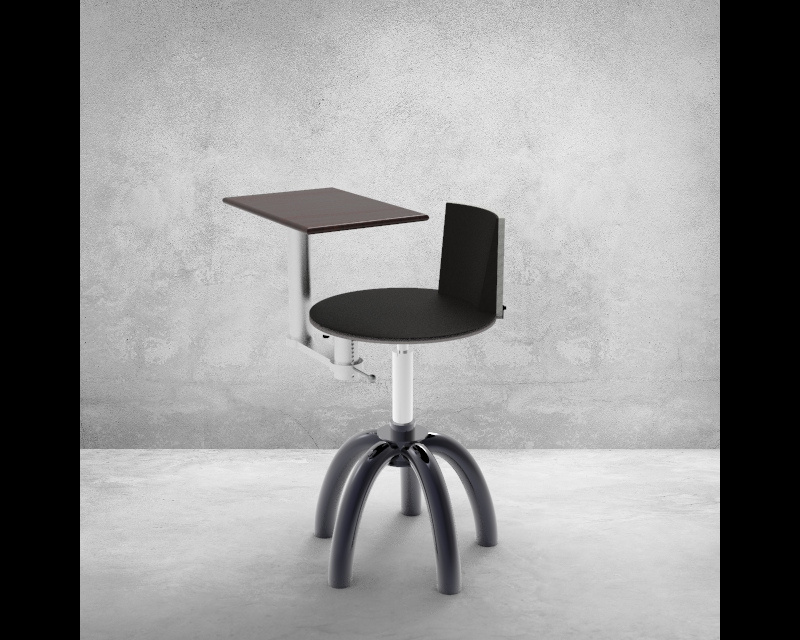

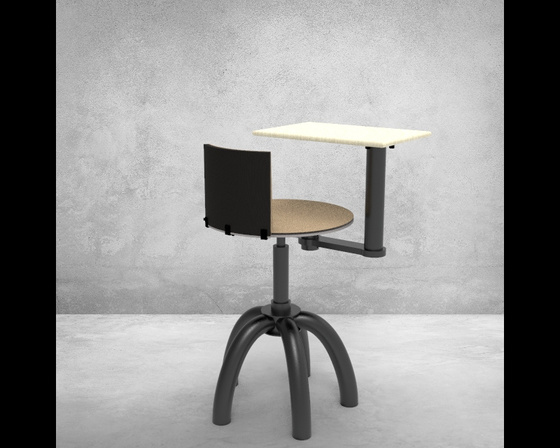

This was a capstone project where the university gave guidelines to design and develop a product. After an extensive market survey a problem with universities seating solution was identified. For the same, I led a cross-functional team in designing and producing ergonomic chairs, ensuring compliance with BIS standards; incorporating features that catered to left-handed and right-handed users, resulting in a 50% increase in customer satisfaction.

Developed ergonomic chair designs using SolidWorks and Ansys, tailoring to diverse body types of 50+ students; ensured optimal comfort and support, reducing reported back pain cases by 40% within the first semester

Executed a cost-effective approach, ensuring adherence to standardized guidelines for university adoption and enhanced future repairability; decreased annual maintenance expenses by 15% by performing stress analysis on chair structures, ensuring durability and safety

Wing Design and Analysis for a Solar-powered Fixed-wing Unmanned Aerial Vehicle

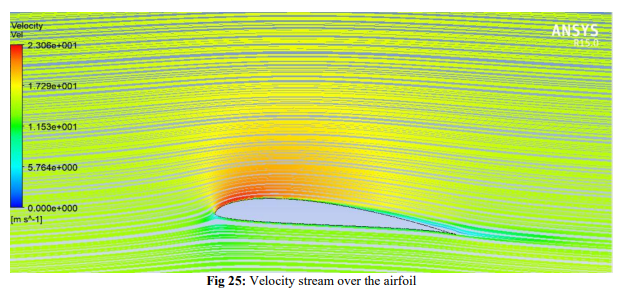

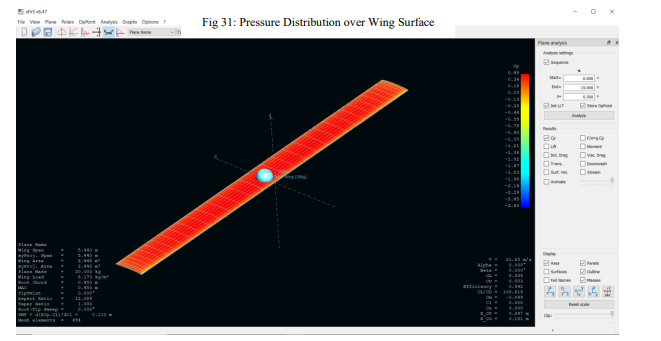

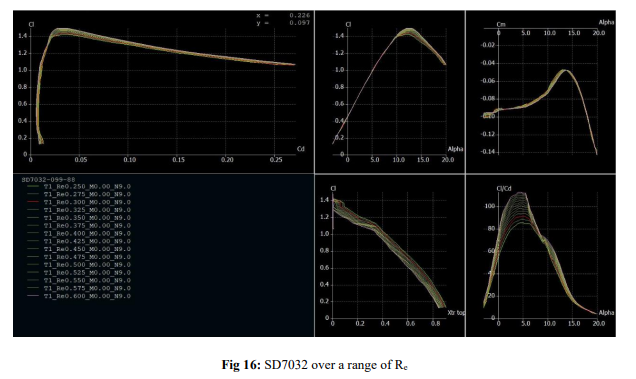

In this project, a solar irradiance model was developed, and a UAV wing was designed in accordance with long haul flights.

I conducted an exhaustive literature review focusing on aerospace subjects, specifically emphasizing High-Altitude Long-Endurance (HALE) UAVs and conventional RC planes.

Led the conceptualization and execution of 3D wing designs and CFD flow analyses to optimize performance.

Did an in-depth airfoil design and rigorous analyses using Ansys Fluent and XLRF5 to enhance aerodynamic efficiency, resulting in 10% reduction in energy consumption and increased range for aircraft models, contributing to significant cost savings.

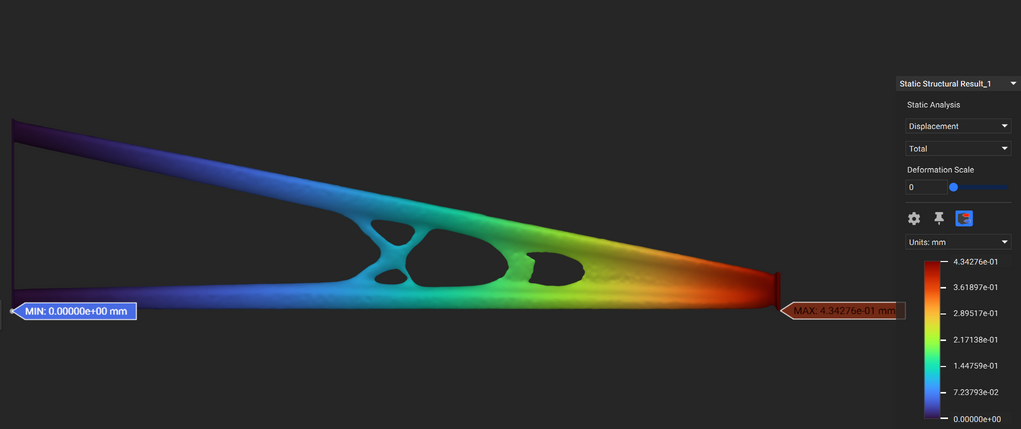

Topology Optimization

A bracket is optimized to save maximum weight in accordance to the manufacturing capabilities of 3D printer available.

Golf Plane corrector

Golf accessories to help you train was designed so that while swinging the plane of the driver is kept at an optimal angle. The device was 3D printed so that the angles can be adjusted with each person's height.

Education

New York University, Tandon School of Engineering

Masters in Science, Mechanical Engineering

(September 2022-December 2023)

GPA 4.0

Sponsored Thesis: “METADATA ANALYSIS FOR DIGITAL MANUFACTURING DATA FILES”

Coursework: Additive Manufacturing of metals, Additive Manufacturing Fundamentals, Non-Destructive Evaluation, Linear Control Theory, Solid Mechanics, Thermal Engineering, Applied Mathematics.

Thapar Institute of Engineering and Technology

(July 2017-June 2021)

BACHELOR OF ENGINEERING, Mechanical Engineering

GPA 9.07/10

Coursework: Computational Fluid Dynamics, Gas Dynamics and Turbo Machines, Machines Design 1-2, Machining Science, Dynamics and Vibration, Manufacturing Technology, Mechanics of Deformable Bodies, Manufacturing Technologies

Work Experience

Prof. Nikhil Gupta NYU, Research Assistant

(September 2023-January 2024)

- Worked in support of the Cyber NYC project sponsored by Google and NYU CATT center to publish my thesis on “METADATA ANALYSIS FOR DIGITAL MANUFACTURING DATA FILES.”

- Developed a novel Machine Learning model for a better 3D CAD search model to search for copyright infringements effectively.

- Achieved 99.7% accuracy in model performance by employing a 4-class system, showcasing the model's proficiency in distinguishing between distinct classes.

- Demonstrated the model's potential for scalability by proposing to incorporate additional classes, with each class representing an existing design file. This expansion promises increased adaptability in comparing new files across a broader spectrum of existing designs.

IIT Bombay, Mechanical Design Engineer Researcher

(January 2020-June 2020)

- Completed IIT Bombay Research Internship 2019-20 in the following sponsored project undertaken in the Institute titled “IC engine study and analysis of H2 rich syngas as fuel”.

- Devised an optimization strategy for gasifying garden waste and plastic pellets to synthesize Syn Gas, reducing reliance on traditional energy sources and achieving a 25% increase in energy efficiency.

- Innovated by implementing syn gas derived from gasification to power a Honda generator, resulting in significant electrical power production and minimized environmental impact.

- Engineered a 15% efficiency surge by fine-tuning pellet dimensions and shapes using different grit sizes and optimized char generation techniques, resulting in enhanced reliability by eliminating choking.

Honda Cars India Ltd, Mechanical Design Engineer Intern

(June 2018-July 2018)

- Completed the project titled "Studly & Preparation of Study Material on HEV and EV" at Honda India.

- Implemented a tailored training program, leveraging industry best practices, to facilitate the smooth workforce transition from IC Engines to Electric Powertrain, resulting in a 50% reduction in training time and seamless adoption of new technology.

- Orchestrated the strategic process planning for Honda's vision of manufacturing HEV and EV vehicles in India; facilitated workforce safety policies and procedures training for an easy and flexible transition to work on HEV and EV powertrains.

- Analyzed 5+ technical reports and documents pivotal for the engineering advancement of various parts

Skills

Mechanical / Product Design

- CAD modeling (SolidWorks, Creo, Onshape)

- Topology Optimization

- Drafting and GD&T

- Rapid Prototyping / 3D printing

- Statistical tolerance analysis

- Using a mill, lathe, band saw, drill press, and other power tools

- Design thinking methods

- Developing product requirements

Testing

- Fixture Design

- Tensile Testing (Instron, etc.)

- Reliability Testing

- ESD Testing

- Failure Mode and Effects Analysis

Softwares

- MATLAB, Arduino, Python, C, C++

- Machine Learning ( TensorFlow)

- XLFR5

- Simplyfy3D, Cura

- ANSYS, Simulink

- nTopology

- Keynote

- MS Office suite

Project Management

- Microsoft Project, Slack

- Financial awareness

- Documentation

Interpersonal

- Client communication & vendor management

- Presenting to large audiences and higher managers

- Multi-disciplinary teamwork

- Leadership training

About Me

I am a tech-savvy individual with a master's degree in mechanical engineering with a specialization in Additive Manufacturing and Structural Dynamics, seeking employment. I am passionate about consistently advancing my knowledge and skills.

While I do keep myself busy with academic and professional endeavours like the one listed above, in my free time you might find me keeping up with my favourite NBA players or scrolling through Formula 1 reels on my Instagram feed, playing basketball and exploring new avenues and experiences that challenge me physically and mentally.